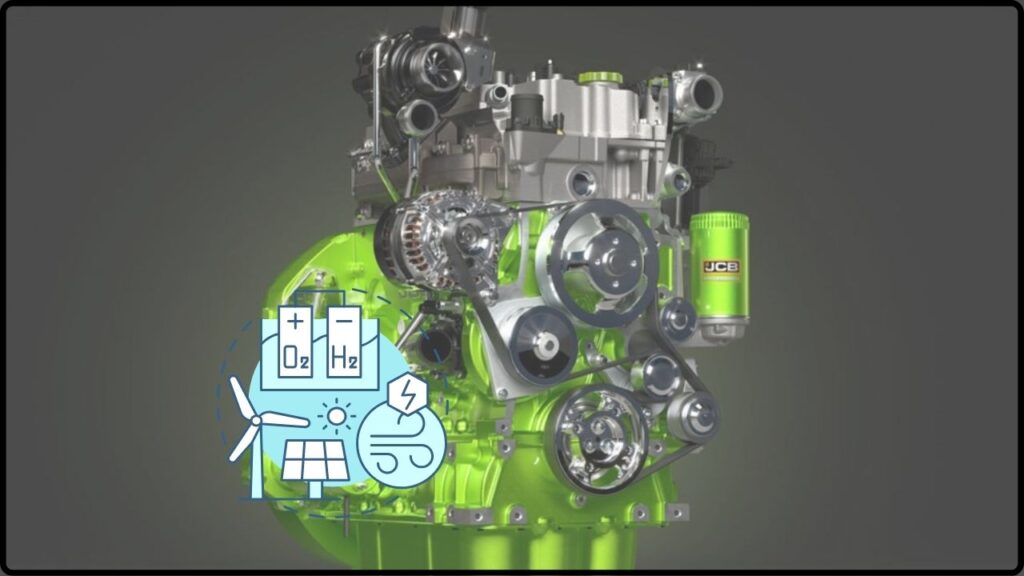

JCB’s Game-Changing Hydrogen Engine: If you’ve been keeping your ear to the ground in the clean tech world, you’ve probably heard whispers—maybe even roars—about JCB’s hydrogen combustion engine. But this ain’t just another concept vehicle making rounds at trade shows. This machine’s already field-tested, certified, and running in the wild. So let’s get real—what exactly is JCB building, how does this hydrogen-powered engine work, and why are some folks calling it Tesla’s biggest threat yet? Well, it all comes down to a simple idea with massive potential: Burn hydrogen instead of diesel—no carbon, all power. That means zero tailpipe CO₂, quick refueling, and performance rugged enough to handle the toughest construction sites on Earth.

JCB’s Game-Changing Hydrogen Engine

JCB’s hydrogen engine is a bold, brilliant step in a new direction—combining the reliability of combustion with the clean power of hydrogen. It’s already certified, tested, and delivering results, and while it may not replace Teslas on city roads, it’s making a real play for the heart of the industrial and heavy equipment market. This isn’t a “someday” solution. It’s ready now—and for professionals who rely on uptime and power, it’s a cleaner, smarter path forward. If Tesla redefined what the car could be, JCB is doing the same for the machines that build our world.

| Metric | Details |

|---|---|

| Technology | Hydrogen Internal Combustion Engine (H2-ICE) |

| Fuel Type | Compressed hydrogen gas |

| Emissions | Zero CO₂, near-zero NOₓ |

| Refueling Time | 3–5 minutes (comparable to diesel) |

| Field Deployment | Over 130 real-world demo units |

| Main Industries | Construction, agriculture, off-road, logistics |

| Regulatory Milestone | Full EU Stage V Type Approval |

| Official Source | JCB Hydrogen Engine |

What Is the JCB Hydrogen Engine?

At its core, the JCB hydrogen engine is an internal combustion engine redesigned to run on pure hydrogen gas instead of fossil fuels. This isn’t a hybrid, and it isn’t a fuel cell. It’s a traditional engine—pistons, crankshaft, turbocharged—that just so happens to burn clean hydrogen and release only water vapor instead of carbon dioxide.

JCB spent over £100 million and employed a team of 150 engineers to develop this engine from scratch, making it a cornerstone of their plan to lead the charge toward decarbonized heavy equipment.

Instead of reinventing the wheel with complex electric systems and long charging times, JCB decided to stick with what works—high torque, fast refueling, long range—and make it clean.

What Makes It Different From Electric Vehicles?

Electric vehicles (EVs), like those made by Tesla, are amazing for city driving, consumer transport, and even regional logistics. But when you’re running heavy machines on tough job sites where there’s no time to charge and no room for downtime, batteries just don’t cut it.

That’s where hydrogen combustion engines shine. Let’s break it down:

Hydrogen Combustion (JCB):

- Quick 3–5 minute refueling

- Keeps diesel-level power and torque

- Familiar mechanical layout

- Zero CO₂ emissions at the tailpipe

- Easier to retrofit into existing equipment platforms

Battery Electric (Tesla and others):

- Long charging times (30 minutes to 8 hours)

- Requires heavy battery packs

- Lower emissions if powered by renewables

- Best for short routes and urban use

- Expensive to build and maintain large-capacity systems

In sectors like construction, agriculture, mining, and remote logistics, hydrogen is increasingly looking like a better fit than batteries—at least for now.

Real-World Use: Tested and Working Today

JCB isn’t just playing with prototypes. More than 130 hydrogen machines have already been tested in:

- Working construction sites

- Agricultural farms across the UK and Europe

- Transport pilots with hydrogen-powered delivery trucks

In fact, one of the biggest wins for JCB came in early 2025, when they received full EU Type Approval for their hydrogen engine under the strict Stage V emissions regulations. That means they’re legally approved for full commercial sale across all EU countries, plus EFTA/EEA zones.

To put that in perspective, most new tech has to go through years of red tape. JCB got the green light early, thanks to their zero-emissions performance and robust safety design.

Hydrogen vs. Battery: Let’s Compare Head-to-Head

| Feature | JCB Hydrogen Engine | Battery Electric Vehicles |

|---|---|---|

| Refueling/Charging Time | 3–5 mins | 30 mins–8 hours |

| Range/Runtime | 6–8 hours | 4–6 hours under load |

| Weight | Lighter engine + fuel tanks | Heavy battery packs |

| Power Output | Diesel-equivalent | Varies, can be limited |

| Infrastructure | Limited, but growing | Extensive in urban areas |

| Upfront Cost | Higher due to H2 systems | High due to batteries |

| Maintenance | Familiar ICE parts | Fewer moving parts but newer tech |

| Carbon Footprint | Zero tailpipe emissions | Grid-dependent emissions |

| Ideal Use Cases | Construction, farming, transport | Urban transit, consumer vehicles |

Infrastructure: Is Hydrogen Ready Yet?

Let’s be honest—hydrogen infrastructure is still in its infancy compared to electric charging stations. But it’s growing quickly, especially in Europe, Australia, Japan, and the U.S.

According to the U.S. Department of Energy, as of 2025, there are:

- < 100 public hydrogen stations in the U.S.

- Many more under development in California, Texas, and New York

- Over 250 stations in Europe, primarily in Germany, the UK, and the Netherlands

To make it work, many large operations (like fleet depots or construction hubs) are investing in on-site hydrogen generation using electrolysis powered by solar or wind. This reduces delivery costs and ensures clean production.

Companies like Shell, BP, and Air Liquide are investing billions in hydrogen infrastructure. Once the backbone is there, hydrogen machines can operate just like diesel—fast, reliable, independent.

A Boost for Skilled Workers and the Economy

One overlooked benefit of hydrogen combustion is its support for existing workers and supply chains. Unlike EVs, which need brand-new training, tools, and logistics, hydrogen engines preserve:

- Engine manufacturing jobs

- Diesel mechanic skills

- Traditional vehicle repair shops

This lowers the barrier for adoption, especially in rural areas and developing markets. It also means countries can transition faster—without completely tearing down what already works.

Environmental Impact: What About the Hydrogen Source?

Not all hydrogen is created equal. Here are the types:

- Green Hydrogen: Made from water using renewable electricity. Cleanest and most sustainable.

- Blue Hydrogen: Made from natural gas, but with carbon capture.

- Grey Hydrogen: Made from fossil fuels. Cheaper, but polluting.

JCB is advocating for green hydrogen adoption, and many of their demos use electrolyzers to create clean hydrogen on-site.

While critics argue that hydrogen is inefficient compared to batteries (and they’re right in some cases), in heavy-duty sectors, the trade-off is worth it. When downtime costs thousands per hour, efficiency isn’t always the biggest concern—reliability and uptime are.

Policy and Market Trends

Governments around the world are rolling out hydrogen incentives:

- The EU Hydrogen Strategy aims for 10 million tonnes of green hydrogen per year by 2030.

- In the U.S., the Inflation Reduction Act includes hydrogen tax credits of up to $3/kg for clean production.

- Australia, Japan, and Canada all have national hydrogen roadmaps with funding for infrastructure and vehicles.

These policies are designed to cut emissions, boost clean jobs, and reduce fossil fuel imports—all aligning with what JCB is offering.

No Gas, No Diesel; Rehlko’s New Engine Shocks America with Bold Electric-Hydrogen Fusion

It’s Official: Japan’s New Zero-Emission Car Could Make Gas-Powered Vehicles Obsolete

Confirmed – U.S. Makes Radical Decision on Autonomous Vehicles—Tesla and GM Are Already Gearing Up

Step-by-Step Guide to Adopting JCB’s Game-Changing Hydrogen Engine

- Assess Usage: Look at daily runtime, fuel consumption, and downtime costs.

- Run TCO Comparisons: Compare hydrogen to diesel and electric based on your region’s fuel costs.

- Plan Refueling Logistics: Partner with local hydrogen suppliers or set up a small electrolyzer system.

- Pilot a Machine: Try a JCB hydrogen unit for 30–60 days in the field.

- Train Your Team: Mechanic and operator training takes less time than you think.

- Monitor, Scale, Optimize: Track performance, costs, and carbon savings—and scale accordingly.